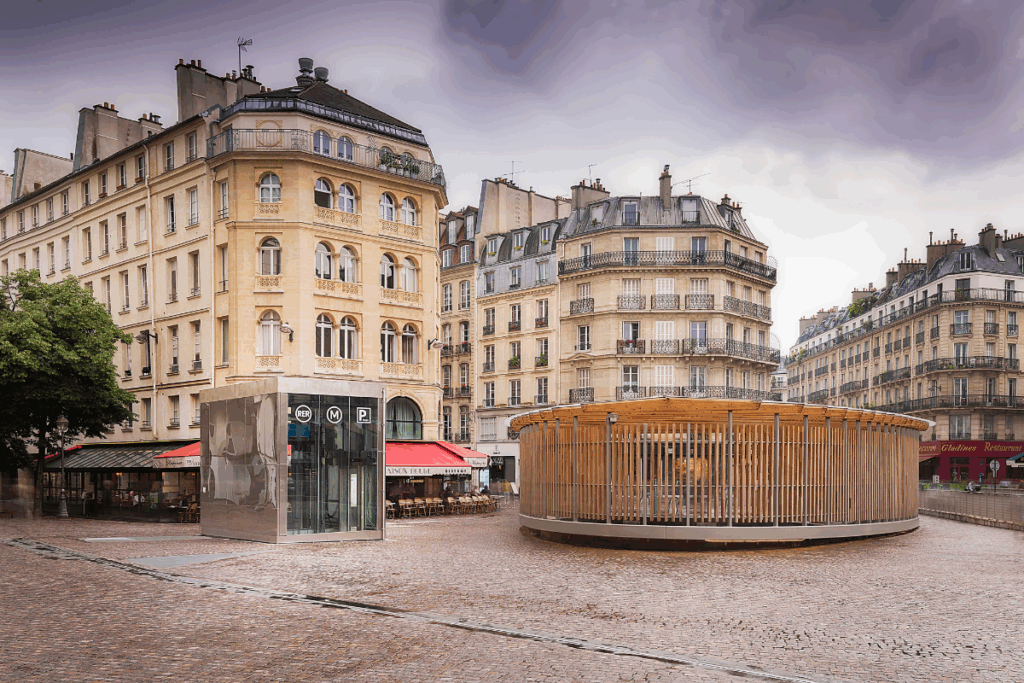

Paris, France

Paris Metro

We design, manufacture, install and maintain all kinds of lifts for the Paris Metro since 1999

IMEM in Paris

IMEM Lifts has been an officially approved supplier to the RATP since 1999

Based on the number of lifts installed and the overall sales revenue, IMEM is the RATP’s most important supplier in the vertical transportation field.

30% of the Paris underground's 500 plus lifts have been manufactured by IMEM Lifts.

Fifty two Paris tube stations are equipped with IMEM lifts.

Special partnership

IMEM prepares specific documentation for the RATP’s maintenance division.

Ventajas

IMEM Lifts has been an officially approved supplier to the RATP since 1999

Based on the number of lifts installed and the overall sales revenue, IMEM is the RATP’s most important supplier in the vertical transportation field.

30% of the Paris underground's 500 plus lifts have been manufactured by IMEM Lifts.

Fifty two Paris tube stations are equipped with IMEM lifts.

Special partnership

IMEM prepares specific documentation for the RATP’s maintenance division.

Ventajas

IMEM Lifts has been an officially approved supplier to the RATP since 1999

Based on the number of lifts installed and the overall sales revenue, IMEM is the RATP’s most important supplier in the vertical transportation field.

30% of the Paris underground's 500 plus lifts have been manufactured by IMEM Lifts.

Fifty two Paris tube stations are equipped with IMEM lifts.

Special partnership

IMEM prepares specific documentation for the RATP’s maintenance division.

Each lift is custom designed and manufactured to order.

Year working life period

Remote monitoring of lifts via internet in real time

Each lift has two separate communication channels.

First RATP’s proprietary MODbus protocol and second a BMS voltage free contact. Through these channels, the lifts automatically send information every second using 5 identifiers, 8 traffic management indicators and 83 equipment status indicators.

Each lift has two separate communication channels.

First RATP’s proprietary MODbus protocol and second a BMS voltage free contact. Through these channels, the lifts automatically send information every second using 5 identifiers, 8 traffic management indicators and 83 equipment status indicators.

The development of new products for the RATP’s specific needs

The design of an MRL (machine-roomless) lift

MRL lifts are now the first-choice technological solution in the international lift sector

The design of heavy-duty freight lifts to service the RATP’s repair workshops.

Both electric and hydraulic solutions of up to 7200kg.