Our client made it clear that, given the characteristics of the building concerned, which is located in one of the most exclusive neighbourhoods in the British capital and whose residents expect only the very highest standards, and given the fact that the lift would be used to carry high-security armoured Rolls-Royces and Bentleys, we would have to design a made-to-measure lift system which was very robust, was equipped with a range of special features and provided a smooth and comfortable ride in accordance with the particular needs and expectations of their clientele.

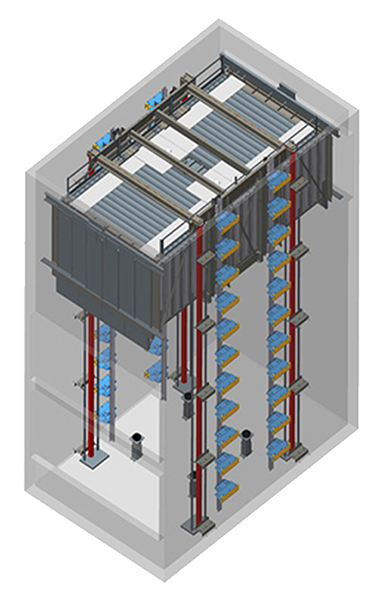

IMEM’s engineering and R&D departments set about studying the particular site conditions and the specifications requested by our client with the aim of producing the best possible solution for the job in hand. The result was a stand-out car lift with the following technical features and characterististics:

- A rated load capacity of 6000 Kg (13,228 lbs), in full compliance with EN 81-2:1998+A3:2009.

- A rated speed of 0.45 metres/second.

- Hydraulic traction with 4 guided telescopic pistons, up to 58 starts per hour.

- Three stops with a maximum travel of 7100mm and a 180º double entrance configuration.

- Lift car: 4518mm wide, 6620mm deep and 2210mm high, to fit existing well.

- Six-panel telescopic doors, an overall width of 3200mm and a height of 2100mm.

- The pit depth of 1200mm and overhead clearance of 3400mm conform to the minimum required by the size of the unit.

- The machine room is located at a distance of 5 metres below the pit, due to the particular characteristics of the building concerned.

6000 Kg

3 stops

Rated speed: 0,45 m/s

Extras

Once the client had approved the design presented by IMEM Lifts, a number of special extras were added in response to the special requirements of the building’s proprietors:

- The extra-large lift car is equipped with two operating panels and strip switches in a selection of colours which are mounted on the side walls and can be operated by the vehicle driver irrespective of his precise parking position inside the lift car.

- The external doors are equipped with a traffic-light system which informs the waiting driver of the lift car’s availability, a green light indicating that the car is free and a red light indicating that the car is currently occupied by another vehicle.

- The car lift is equipped with a visual signal system to ensure the correct positioning of the vehicle within. Two photoelectric light curtains detect the vehicle’s position and one of the two arrows on the operating panel lights up according to whether the driver should move forwards or backwards to position the vehicle correctly and avoid interfering with the opening and closing of the automatic doors.

- Remote controls are included for driver/passenger convenience, allowing the lift to be called without leaving the vehicle.