The design, manufacture & installation of lifts in the Lamarck-Caulaincourt Metro station in Paris

The Lamarck-Caulaincourt métro station first opened in 1912 and takes its name from the two main roads that cross near its entrance in the Rue Pierre-Dac, a doorway that sits in between two staircases that lead up to Montmartre. Inside, the platforms are 25 metres (82 feet) below street level.

The old lifts had become incapable of dealing with the enormous flows of passenger traffic through the station and, as a result, IMEM Lifts – already a major supplier to the RATP (Paris’s public transport authority) – was hired to design a brand-new lift system to resolve the station’s serious congestion problems.

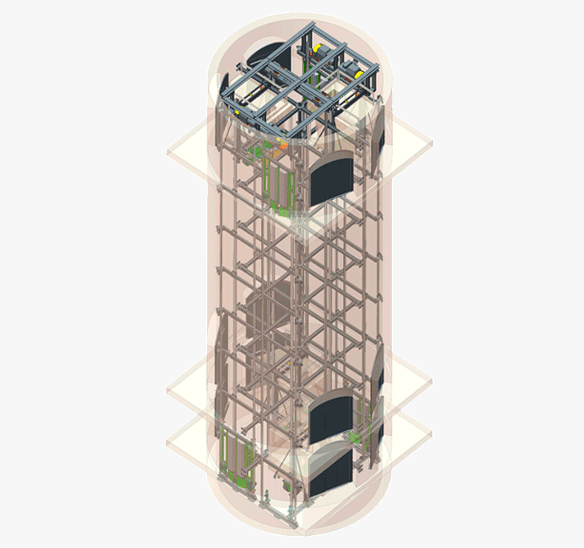

After carrying out a detailed study of this centrally-located site, IMEM proposed the complete removal of the old lifts and their replacement with two banks of four lifts, each with a 2250Kg (34-passenger) load capacity and a rated speed of 1.6m/s. The four lifts in each bank travel within a large cylindrical shaft, which is divided into four sections by 25-metre-high metallic separators that were also designed, manufactured and installed by IMEM Lifts.